|

Solar Cooker types: Solar cookers can be generically classified in three families: First we have the concentration type cookers. These use reflecting surfaces to concentrate radiation in a focal point. Most use a parabolic reflector. Temperature rises quickly, and cooking can be done fast. However one must refocus them every 10 to 15 minutes and food must be stirred (to keep it from sticking to the pots). These are the only type of cookers that can fry. Then we have the panel cooker type. These are very simple and low cost designs. They generally use aluminized cardboard reflectors and the pot is put in the center covered with a transparent plastic.They do cook, but slowly and ambient temperatures need to be high, over 28°C to cook properly. Finally we have the oven or box type of cooker. These have an insulated box, topped with a transparent cover (typically two plates of glass) and an external reinforcing reflector. This is the type we prefer, since cooking can be done almost unattended, and they're very safe to operate. |

|

|

|

In Perú the parabolic SK-12 cooker is being mass produced. This german design incorporates a deep parabolic concentrator to avoid dazzling the operator. The reflecting surface is made of sheets of high reflection aluminum (the same that's used in high quality fluorescent fixtures). This material has a high reflection coefficient and withstands the outdoors. In Perú there's over 200 of these in operation, mostly in the Puno region (near lake Titicaca). Manufacture is going at the rate of 10 to 20 units a month. They are popular, since they're well adapted to Peruvian cooking tastes. The cost is around US$150 per unit. |

|

The same SK-12 model is also being used in Costa Rica. But the model we see in the picture has been imported. This has meant that the use of cocentrating cookers in Costa Rica is not plentiful. This is also influenced by the fact that partially cloudy conditions are common. Parabolic cookers lose temperature very fast under partially cloudy conditions. Also, cost is a factor, since they're not manufactured locally. |

|

|

This is an example of a panel solar cooker. It's made of aluminized cardboard. The pot is wrapped in a microwave resistant plastic bag. This model is not very efficient, which means long cooking times and the necessity of rather high ambient temperatures for it to work. But it's very low cost (on the order of US$5 to 10). This means that tens of thousands of units have been manufactured for refugee camps in Africa. Now some are being used by poor families in Jujuy and Mendoza, Argentina. |

|

|

Figure 4: Fresnel concentrating reflector in Salta Argentina |

In Salta, Argentina, a very novel type has been developed. The concentrator is a Fresnel type reflector. In the focal region, solid aluminum bricks are heated up to 400ºC. Then the hot bricks are put in an insulated oven in a school. The oven permits either the baking of bread or cooking for up to 20 to 30 kg of food. Another variant heats water in the focal region, producing steam, which can be used to directly boil food in the cooking pots. |

|

The parabolic solar cookers that operate in Villaseca (Chile) have been working for over 10 years. The parabola is made of FRP, is not very deep and is covered with small glass mirrors of about 20x20mm size. |

|

|

|

The focal zone is fixed and the parabola rotates about it. This permits putting more than one pot near the heating zone. Also the system can be operated from behind. This avoids dazzlement for the operator as well as simplifying orientation. This project was conceived and started by INTA (Instituto de Tecnología de Alimentos, U. de Chile, Food Technology Institute of the University of Chile). The parabolic design cookers are due to Pedro Serrano. |

|

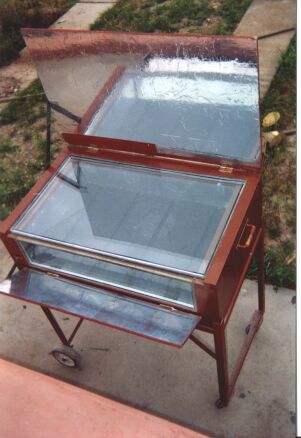

The second type of cookers are the oven or box type cookers. In these, solar radiation enters an insulated box through a transparent cover (typically a double glass cover). They can't raise as high a temperature as parabolic cookers, but they attain sufficient temperature for cooking and need much less attention to the cooking process. They also retain heat much better. Generally, this type is preferred by most users. |

|

|

Figure 7: Box type cooker in Guanacaste, Costa Rica |

This is an example of the box type solar cooker widely used in Costa Rica. The original design is by Dr. Shyam Nandwani, from the Universidad Nacional de Heredia (San José). Loading is from the front an the glass cover is horizontal. Costa Rica is near the equator, so horizontal glass works very well year around. This type of model is popular throughout Central America, with hundreds of units in operation. The reflector is also used as a cover when the cooker is not working. |

|

Taking the basic design from Costa Rica, a similar model is made in Perú. The box is made from tin plates (recicled from can metal that has printing defects) and the reflector is made from the same aluminum used in the parabolic SK-12 cookers. This type works very well, but most users in Perú prefer the SK-12 cooker. |

Figure 8: Another box type model, this one in Lima, Perú |

|

|

The same basic design from Costa Rica has also been adapted for Mendoza, Argentina. Due to the higher latitude, glazing covers both the top and front surfaces. This permits the cooker to work for more months. But a greater glazed surface means higher thermal losses. |

|

In Mendoza, Prof. Alfredo Estévez used building workshops to make sooler cookers in this province. The workshop is an excellent method if making the cooker is not too complicated. This is because people tend to "make their own" the pieces they've worked on. But strict supervision is necessary, because if errors are made during building, performance suffers and this might discourage prospective users. |

|

|

Figure 11: Box type cooker inVillaseca, Chile |

The "Artesanas Solares de Villaseca" project is well known in Chile and even in other countries. This box type cooker has been in daily use for over 10 years. This one is installed in the house of one of the original monitors of this project. The design, made by Víctor Pinto, an engineer, is notable for its simplicity as well as low cost. |

|

The one we see in this photo is the same as the other one, except it was made recently by the same women that are the motor behind the project. This one is located in the Solar Restaurant that is operating in Villaseca. This small cottage enterprise has several years of succesfull operation. |

|

|

|

The restaurant operates year round with a standard menu. All cooking is done by solar energy. The "Artesanas Solares de Villaseca" have spread their knowledge and techniques to other places in the region, including Combarbalá and other small towns. Solar cookers save energy, time and forest cover. If you arrived here from an external link, please visit our homepages at www.ecomaipo.cl. |